Aircraft engines work under extreme heat and pressure. Turbine blades inside these engines handle some of the toughest conditions. Because of this, regular inspections are essential. One of the most effective ways to check turbine blades without taking the engine apart is by using a borescope.

A borescope lets technicians see inside tight spaces and capture clear images and videos. With the right process and tools, inspections become faster, safer, and more reliable. They provide equipment that helps maintenance teams get detailed visual access to critical engine parts.

Here is a clear, step-by-step guide to inspecting turbine blades with a borescope.

Step 1: Review the Engine Maintenance Manual

Before starting any inspection, always review the aircraft and engine maintenance manuals. These documents tell you where to insert the borescope, what areas to inspect, and what types of damage to look for.

Different engines have different access ports and inspection intervals. Following the correct procedure protects both the engine and the technician. It also ensures the inspection meets regulatory and manufacturer requirements.

Step 2: Gather the Right Equipment

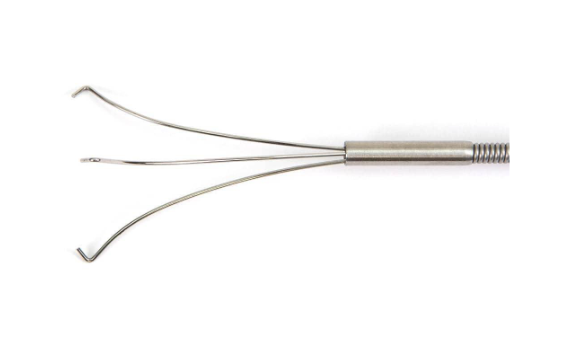

Using proper tools makes a big difference in inspection quality. At a minimum, you will need:

- A high-quality aviation borescope

- Light source built into the scope

- Recording device or software

- Cleaning materials for the insertion area

- Personal protective equipment

They offer aviation-ready systems that provide clear imaging, flexible insertion tubes, and recording features. They design their equipment to handle the tight bends and the great detail needs of turbine inspections.

Make sure batteries are charged, and memory storage is ready before starting.

Step 3: Prepare the Aircraft and Work Area

Safety comes first. Confirm the engine is completely shut down, cooled, and safe to access. Follow lockout and tagout procedures if required by your organization.

Clean the area around the borescope access port. Dirt or debris near the opening can fall into the engine and cause damage. Use lint-free cloths and approved cleaning agents.

Set up your monitor or tablet so you can view the borescope feed clearly while working. Good visibility helps you spot small defects early.

Step 4: Insert the Borescope Carefully

Slow and gentle movements are key. Insert the borescope through the designated access port without forcing it. The insertion tube should move smoothly. If you feel resistance, stop and reposition.

Modern scopes are built with flexible articulation. They allow technicians to steer the camera tip around curves and toward specific blade rows. Use the control knobs slowly to guide the tip.

Avoid touching blade edges with the scope whenever possible. While turbine blades are strong, they can still be damaged by rough handling.

Step 5: Adjust Lighting and Focus

Proper lighting is essential for a clear inspection. Too much light can cause glare, while too little hides important details. Adjust the brightness until the blade surface appears clear and evenly lit.

Next, focus the image. Many aviation borescopes have adjustable focus or auto focus features. A sharp image allows you to see small cracks, pits, or surface wear.

Take your time here. Good image quality leads to better decisions later.

Step 6: Follow a Consistent Inspection Pattern

To avoid missing anything, inspect turbine blades in a consistent order. Start with one blade and move around the entire row. Then shift to the next stage if accessible.

Look at:

- Leading edges

- Trailing edges

- Blade tips

- Root areas

- Surface coatings

Move the scope slowly across each area. Sudden movements can blur the image and make it easy to miss damage.

Using recording features from them helps you review footage later and share it with other maintenance staff if needed.

Step 7: Identify Common Types of Blade Damage

During the inspection, you are looking for signs that a blade may be worn or failing. Common issues include:

Cracks

Small cracks can grow over time. They often appear near the root or along edges. Even short cracks should be documented.

Burn Marks or Heat Damage

Discoloration or surface changes may indicate overheating. This can weaken the blade material.

Pitting and Corrosion

Tiny pits or rough spots can form from contaminants or environmental exposure. These can affect airflow and performance.

Foreign Object Damage

Nicks or dents from debris are common. Look closely at leading edges where impacts usually occur.

Coating Loss

Protective coatings help blades handle high temperatures. If the coating is flaking or worn away, the base metal may be at risk.

Take still images or video clips of any concern areas.

Step 8: Capture Clear Documentation

Good records are just as important as the inspection itself. Save images and videos with clear labels. Include:

- Engine serial number

- Aircraft tail number

- Date of inspection

- Blade stage and position, if known

- Description of any findings

Digital recording features make this process easier. They design their systems to store and transfer files quickly, helping teams keep organized maintenance logs.

Clear documentation supports maintenance decisions and helps track changes over time.

Step 9: Compare Findings With Service Limits

Once the inspection is complete, compare any defects you found with the limits in the maintenance manual. Some minor damage may be acceptable for continued operation. Other findings may require repair or part replacement.

If you are unsure, share the images with an engineer or senior technician. Having high-resolution visuals makes remote review more effective.

Never guess when it comes to engine components. Always rely on approved data and expert input.

Step 10: Remove the Borescope and Secure the Engine

When the inspection is done, slowly withdraw the borescope. Watch the live image while removing it to avoid catching the tip on internal parts.

Inspect the insertion tube for oil, debris, or damage after removal. Clean it according to the manufacturer’s instructions.

Reinstall any access plugs or panels and torque them as specified in the manual. Make sure the engine is returned to a safe and secure condition.

Step 11: Review and Plan Next Steps

After everything is put back together, review your images and notes. Decide whether the engine can remain in service or if further action is needed.

Trend monitoring is very useful. Comparing current images with past inspections can show whether damage is stable or getting worse. Over time, this helps maintenance teams plan repairs before problems become serious.

By using reliable equipment from USA Borescopes, they help technicians capture consistent images that make long-term tracking more accurate.

Why Borescope Inspections Matter

Borescope inspections save time and money because they reduce the need for engine teardown. They also improve safety by catching problems early.

Turbine blades operate in one of the harshest parts of an aircraft engine. Even small defects can grow under high heat and stress. Regular visual checks give maintenance teams the information they need to act quickly.

With modern imaging technology, technicians can see details that were hard to detect in the past. This leads to smarter maintenance decisions and better aircraft reliability.

Using the right process and high-quality tools makes turbine blade inspections more effective and less stressful.

Upgrade Your Turbine Inspections Today

Ready to improve your turbine blade inspections with clearer visuals and dependable equipment? USA Borescopes offers aviation-grade borescopes, expert support, and fast shipping to keep your maintenance team efficient and confident. Reach out to them today to find the inspection solution for your operation.

About the Author

This guest post was written by an aviation maintenance industry writer with a focus on inspection technology, safety practices, and practical tools that support reliable aircraft operations. They regularly create content that helps technicians, engineers, and maintenance teams better understand inspection methods and equipment. Their work centers on making technical topics easier to follow while promoting safer, more efficient aircraft maintenance procedures across the aviation industry.